CHASED BOSS ON FERRULE and DECORATIVE JEWELER'S OR FRET SAW FRAME

Tom Latane'

June 6,7&8, 2021 and June 9,10,11&12, 2021

These two related classes will run consecutively. Though priority will be given to those signing up for both classes, either class could be taken singly.

CHASED BOSS ON FERRULE Length: 3 DAYS

Suitable for the handle of a tool or knife, this piece will be used on the saw frame by students taking both classes.

Students will forge. heat treat and grind tools which they will then use to chase a stylized acanthus design on a bulbous section forged

and filed on the end of a 3/4" bar. The boss will be drilled and chiseled to receive a tool tang before being cut from the bar.

A ferrule will be fire brazed to the boss to complete the project.

DECORATIVE JEWELER'S OR FRET SAW FRAME

Length: 4 Days

Designed to incorporate the boss described in the first class description, this frame can be fitted with a simpler ferrule by anyone

not taking the other class.

The frame will include a wider section at the top suitable for decorative profiling and piercing.

The end opposite the handle will be fashioned with a square mortise to receive a threaded section with a wingnut for tensioning the blade.

Both ends will have thumb screws for clamping blades.

Axe Making

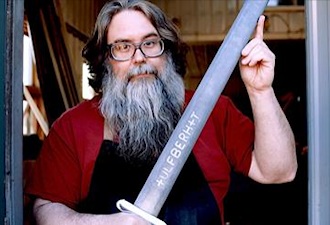

Ric Furrer

August 20, 21 and 22, 2021

We will concentrate on these two designs

Returning Nova celebrity for his expertise with the Viking swords and his knowledge and experience in Damascus, heat treating,

and pattern welded steel.

Rather than a knife this year I thought we should do axes with pattern-welded edges.

Starting with a billet of mild steel you will forge out a mirror image axe shape in preparation for folding and welding.

Using this method we form the eye for the handle with the fold rather than a chisel and drift.

Once the axe blank is rough forged to shape you will weld up a small billet of layered steel which will become the inserted edge.

In this way you get the experience of pattern-welding as well as axe making.

Once the pattern-welded steel bit is fitted inside the blank you will weld the body of the axe to the bit.

From there it is a matter of maintaining the eye shape with drifts and fine tuning the edge.

Light grinding follows next and then heat treating, fitting of the handle, and sharpening.

Over the three days you will gain new skills and leave with a functioning axe of your own making.

These techniques can be applied to other woodworking tools as well so they are good to learn.

SMALL AXE HEAD for NORWEGIAN STYLE WALKING STICK

Tom Latane'

September 10, 11 and 12, 2021

Students will each forge a small axe head like those used on some eighteenth century walking sticks in Norway.

These walking sticks were called Bergmannsstav in Norway where they are thought to have been introduced by German workers in the mining district.

The eye can be forge-welded or punched depending on preference.

The axe head on a Bergmannsstav was purely decorative (some were made of wood).

The shepherd's axe, from Eastern Europe, was similar but indeed usable as an axe.

High carbon steel may be welded in the bit if desired for use, or the edge could remain mild steel.

After being forged, the head will be cleaned in acid pickle and filed.

It may then be chased or pierced or inlaid with non-ferrous wire (though there will not be time for inlaying in the class).

Directions to Tunnel Mill:

28036 Cty Road 1

Spring Valley, Minnnesota

55975

Tunnel Mill is located 20 miles south of Rochester Minnesota. Take Hwy 63 South out of Rochester to Stewartville, turn east on Hwy 30 to County Highway 1 (approx 5.5 miles).

Turn south on County Highway 1. Follow CO HWY 1 6.5 miles to Tunnel Mill on the left side of CO RD

Call about camping on the grounds. 507-378-4983 or 507-289-4189, Carol Adams.

Lodging available in Spring Valley, 5 miles further south on CO RD 1.

Shady Rest 507-346-2625---Spring Valley Motel & Suites-507-346-7788

Class Registration Form

Class Contact Information

For more information on any of the classes contact us at

jc-adams@msn.com, or call 507-289-4189 Carol Adams.

We are located in southern Minnesota. Tunnel Mill was an old water powered mill. Built in 1869.

Retired in the late 1920's..

Located on the Bear River north of Spring Valley, MN.

Wooded 50 acres with a stream that runs through it.

Now, it's a place for crafts people and friends to congregate, relax and learn some of our forgotten crafts.

Watch for more classes!!